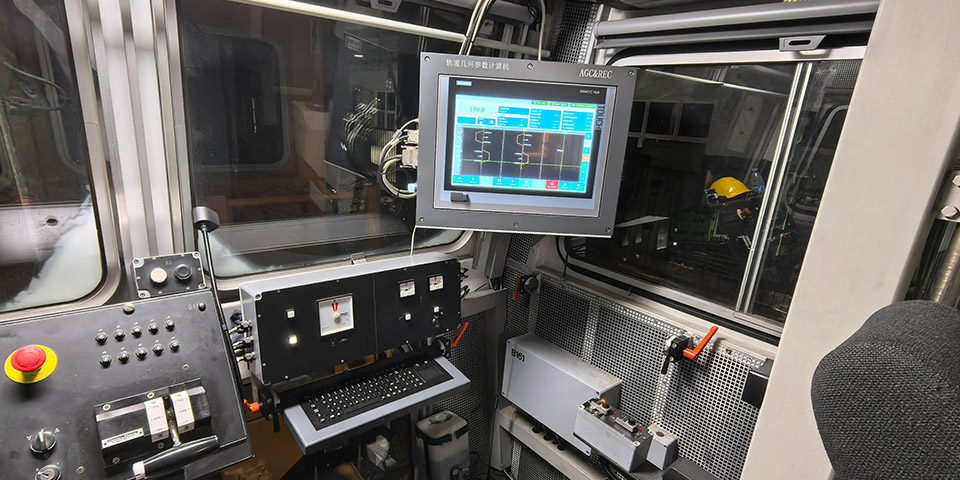

In November 2024, our company's latest new generation AGC (track geometry computer) product was used to upgrade the ALC operation control system on the 08-16SH tamping machine imported by Plasser in the Beijing Section Large Machine Operation and Maintenance Section, including REC recorders, operation data LED display lights, etc.

AGC Application Scope:

• Applicable to any line and any track gauge

• Applicable to any type of tamping vehicle using the chord measurement system

• Applicable to three-point and four-point chord measurement systems

• Applicable to single pendulum compensation leveling system (08 model) and double pendulum compensation leveling system (09 model)

• Appropriately add conversion modules to upgrade and transform traditional analog models

AGC main functional modules:

• Editing, inputting and solving the known theoretical track geometry

• Measuring, running, optimizing and solving the unknown theoretical line

• Supporting the line state repair mode with independent track start on the left and right tracks

• Automatic up and down slope function for basic track start

• Convenient precision measurement and tamping interface (VER file import)

• Integrated eight-channel recorder with operation quality assessment function and line data comparison and analysis function

• Internationally original typical track geometry input template, convenient for users to input unconventional lines

Customer feedback and satisfaction:

Customer feedback shows that they are very satisfied with the upgraded AGC system. The 15-inch PLUS large screen not only has a simple and intuitive interface, but also has full touch screen operation, making it particularly convenient to use. Operation data is also wirelessly transmitted to a large LED screen, which facilitates on-site personnel to monitor the work quality in real time and reduces the trouble of cable wiring. The entire system integrates line calculation, operation recording, and data broadcasting, especially the automatic downhill and reverse operation functions in complex environments, which significantly reduces the possibility of human error. In summary, the upgrade of the AGC system has brought significant improvements in operating efficiency, optimized data management and simplified operation to the 08-16SH tamping truck, meeting customers' needs for efficient, precise and safe operations, and gained Highly recognized by customers

Next: Chengdu Railway Bureau upgrades DWL48 tamping machine: new generation AGC system improves operating efficiency

Interested in learning more about the products we brought to 'Plasser imported 08-16SH tamping machine AGC system upgrade'? Reach out and we can share more of our industry solutions that are helping operations teams reach their production goals.

Let’s talk more